| |

Your Oil Is Talking,

Are You Listening?

Right

now, the oil working in your crankcase, gearbox, or

sump contains information that could be vital to the

performance and productivity of your engine or equipment.

Contaminants that can indicate wear or cause serious

equipment damage such as metals, water, raw fuel,

acids, fuel soot and other solids collect in your

lubricant. Using oil analysis to evaluate these contaminants

is a scientific approach to predictive maintenance,

allowing you a look inside your machinery to spot

mechanical wear and contamination in its early stages.

You'll extend machine life, head off major maintenance

costs and prevent catastrophic failure that can shut

down or leave you stranded, and you'll maximize lubricant

life. Right

now, the oil working in your crankcase, gearbox, or

sump contains information that could be vital to the

performance and productivity of your engine or equipment.

Contaminants that can indicate wear or cause serious

equipment damage such as metals, water, raw fuel,

acids, fuel soot and other solids collect in your

lubricant. Using oil analysis to evaluate these contaminants

is a scientific approach to predictive maintenance,

allowing you a look inside your machinery to spot

mechanical wear and contamination in its early stages.

You'll extend machine life, head off major maintenance

costs and prevent catastrophic failure that can shut

down or leave you stranded, and you'll maximize lubricant

life.

Oil Analysis Provides a

Big Return for Your Small Investment by:

- Extending equipment life

by preventing premature component failure

- Reducing maintenance costs

by eliminating unnecessary component changes and

decrease downtime due to premature scheduled maintenance

- Enabling calculation of

optimum drain intervals that will reduce lubricant

costs and assure maximum equipment protection

- Eliminating complete teardowns

based on guesswork

- Reducing unscheduled maintenance

- keeps equipment up and running

- Enabling better assessment

of equipment performance

Who is Using Oil Analysis?

An

oil analysis program can provide critical information

for any equipment requiring lubricants - both gasoline

and diesel engines, transmissions, gears, bearings,

and hydraulic systems. It's useful for owners of passenger

cars, over-the road fleets, off-highway equipment,

boats, or high performance vehicles. It's also essential

for various industries that focus on managing plant

equipment and maintenance costs. As a matter of fact,

as many as 70% of today's construction equipment operators

use professional oil analysis to assess equipment

and lubricant condition. Forty percent of all transportation

fleets and 20 percent of industrial plants also rely

on lubricant testing as an integral part of predictive/preventive

maintenance. These businesses know that oil analysis

replaces the guesswork in predicting equipment wear

and scheduling optimum drain intervals. The data provided

by oil analysis enables them to maximize equipment

profitability by minimizing maintenance downtime. An

oil analysis program can provide critical information

for any equipment requiring lubricants - both gasoline

and diesel engines, transmissions, gears, bearings,

and hydraulic systems. It's useful for owners of passenger

cars, over-the road fleets, off-highway equipment,

boats, or high performance vehicles. It's also essential

for various industries that focus on managing plant

equipment and maintenance costs. As a matter of fact,

as many as 70% of today's construction equipment operators

use professional oil analysis to assess equipment

and lubricant condition. Forty percent of all transportation

fleets and 20 percent of industrial plants also rely

on lubricant testing as an integral part of predictive/preventive

maintenance. These businesses know that oil analysis

replaces the guesswork in predicting equipment wear

and scheduling optimum drain intervals. The data provided

by oil analysis enables them to maximize equipment

profitability by minimizing maintenance downtime.

The Oil Analysis Program

From Oil Analyzers, Inc.

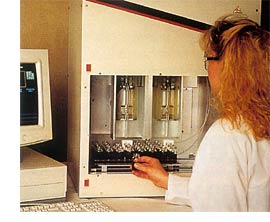

- State of the art Laboratory

and testing instrumentation

- Web based and Email Reporting

for fast turnaround

- User Friendly, Pre-Addressed

Sampling Kits

- Accessible Customer Support

for Questions and Concerns

- Maintained Data History

for Trending Analysis

- Easy To Read Recommendations

|

|